MSG compressors are custom designed and built for individual customer needs for a variety of applications. Our MSG style compressors are manufactured with a highly engineered air flow components, designed for easy, low-cost installation and operation.

Features

MSG? INTEGRALLY GEARED CENTRIFUGAL COMPRESSORS

MSG (multi-stage geared) compressors offer outstanding design flexibility. MSG compressors are application engineered with numerous available configurations:

Flows from 70 to 3800 m3/min (2500 to 135,000 CFM)

Input capacity to over 18,650 kW (25,000 hp)

Discharge pressures to 100 barg (1450 psig)

FEATURES

Prevents system contamination

Reduces the potential for compressed air pipeline fires caused by oil carryover

No costly waste disposal associated with oil-laden condensate

Eliminates the expense and maintenance of oil separation filters at the discharge

High Reliability

MSG centrifugal compressors are designed to be extremely

reliable due to:

Conservative high-quality gear design

Long-life pinion bearing design

Thrust loads absorbed at low speed

Stainless steel compression elements

Low Compressor Operating Life Cycle Cost

MSG centrifugal compressors provide better overall operating efficiency than positive displacement or other centrifugal compressors.

Excellent efficiencies at full load, part load and no load

Low maintenance cost

Increased uptime from high-reliability design (limits the need for multiple unit installations for basic reliability reasons)

No sliding or rubbing parts in the compression process that can cause wear and thereby efficiency loss

APPLICATIONS

Engineered Air Applications

Industrial gases

Instrument air

American Petroleum Institute (API) standards

Soot blowers

Large plant air

Power industry related

Gas Compressor Applications

Fuel gas boosting

Natural gas gathering

Hydrocarbon refrigeration gas

Carbon monoxide

CO2 (wet or dry)

SynGas

Low molecular weight recycle gas

High-pressure nitrogen

Landfill gas

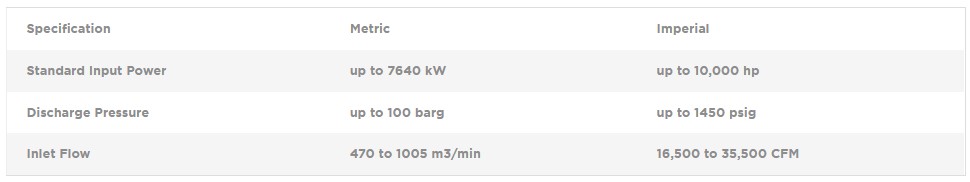

Model specifications